I will be talking about common metal roofing problems cut edge protection to keep your roof in good condition. You must be wondering about how you can ensure that your metal roof won’t give in and last for a long time.

Oil Canning

Stress wrinkling or oil canning appears in all types of metal panels: steel, aluminIum, zinc, or copper.

The metal on a standing seam metal system faces over-stress at times and is unable to hold a flat form creating visible waves. The reasons for oil canning include extreme pressure during the coiling of the metal, frequent stress from coil slitting (cutting) and roll forming panels, and congestion of space for thermal expansion of the panel. One of the major reasons for canning is improper use, handling, and storage by installers. Roofers can reduce canning by using thicker metal, a rib roller profile between panels, using a low-gloss or matte finish to reduce reflectivity, using stretched metal, and installing the roof over a flat “in-place” roof deck.

Leaks can appear anywhere and ruin your home or building. Leaks in Metal roofs are out of our control, and some are due to human error. Causes that could lead to a leaking roof include excessive rain, high winds, and extreme weather occurrences. Technical errors include Failed fasteners, seam, flashing, sealant or butyl tape, and use of inadequate details. It is always good to choose a reliable contractor who uses quality products to reduce leaks.

Scuffing and Scratching

One of the major problems in metal roofing is scratching or scuffing. Of course, reputed manufacturers are cautious and take precaution to ensure the coil is safe during the slitting, recoiling, or transportation.

Despite all care taken by contractors and installers during the roll forming and installation process, there is always the possibility of surface-level damage. Damages happen when the metal is improperly coiled. Consequently, the metal rubs together stripping the coating. Sometimes Edge guards are absent, and there is nothing to protect the sheet edges in transit. Improper lifting devices and malfunctioning in a roll forming machine are other reasons. Sometimes tools are dropped on panels causing scraping and panels face damage at flashing points or ladder entries.

Corrosion

Of course, metal roofing defends against corrosion and degradation for decades, because metal roofing has protective paint systems or coatings. Sometimes special circumstances that could occur may cause problems including underside corrosion due to faulty painting. Saltwater corrosion which is typical in coastal areas because of salt water’s effect on metal. Negative reactions due to the use of Dissimilar metals and Cut edges that can bring edge creep, which is minimal rusting occurring at the cut edge.

Chalking and Fading

This is a potential problem referring to the whitish residue that is visible on a painted or coated metal panel. This is due to the paint resin breaking down from UV exposure. Sometimes the paint on the metal substrate breaks down due to UV rays, or water, resulting in fading.

Chalking and fading depend on the environment and substances the roof endures. But this can be taken care of by good paint warranties that cover chalking and fading problems.

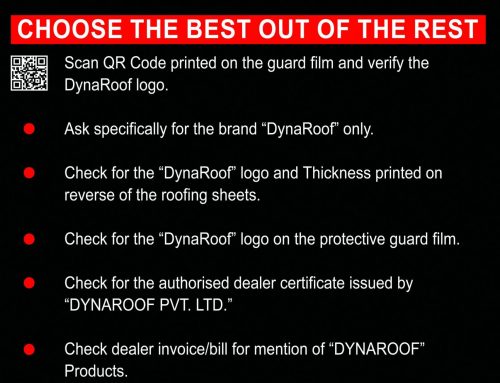

Deal with reputed roofing companies

You should never compromise, when buying the roofing materials, therefore, buy goods from a reputable company that thoroughly tests its products, and stands behind them with warranties. For a quick guide to roofing issues, Dynaroof team is happy to help.

Leave A Comment