Metal Roof Leaks: Lasting Solutions

Leaks are avoided in metal roofs if they are installed in the right way properly preventing the need for sealants. Preventing leaks in metal roofs are particularly challenging as the metal has a high coefficient of expansion, so it moves more extensively with temperature swings. Moreover, metal roofs feature flashings and other details that also move along different directions. Many times mechanical seamers do not work correctly. All these create avenues for water. But products that can remedy the situation effectively are available.

It is easy to repair metal roof leaks with sealants and tape. Ideally, sealants seal the gaps formed by mechanical fastener heads and other penetrations that back out from expansion/contraction cycles. The process of repairing involves removing the screws, putting in a new washer and fastener, and then dabbing a high-quality sealant over each head.

Sealants and Tapes

Generally, high-solids polyether or silicone sealant is best for metal roofs. They are available in pigments that match popular roof colours, so they blend in and form a tight seal. Seals manufactured in polymer types have excellent adhesion to metal, including coated metal. Such sealants are ultraviolet (UV) stable and have excellent weathering and physical properties. In case you need to repair damaged areas, roof tapes are also highly effective and efficient in such situations. For instance, on a lower slope metal roof, on large commercial warehouses, leaks generally occur or form along seams and gaps. In such a situation, a high-quality, watertight roof tape should stem the problem.

All it requires is proper preparation. The area to be taped should be free from dirt and oil residue from the atmosphere. The tape should be pressed with a roller to activate the adhesive.

Gutters and Water

The tape is proper for stemming leaks in gutters, in joints, corners and places where there is no damage, and the precise length and the joint is too big, the tape is good. Cleaning the gutter is crucial as it acts as the sink for all the dirt and grime that comes off the roof. Therefore a thick tape with a coating is a better choice as it can eliminate the need to apply any protective coatings to the sealant tape after installing.

Big commercial roofs often have ponding water caused by heavy AC units that have condensate lines that are supposed to run to the gutter or drain. These can lead to leaks, clog or even get disconnected, thus ponding water.

Industry Standards for Rooftop Attachments

A plethora of non-penetrating seam clamp vendors has appeared in the market with metal roof attachment systems, each claiming to be the first or best. Each product may have a different application system. It is imperative to establish industry standards because they transfer live loads into the roof sheathing and structure, and are life-safety related,

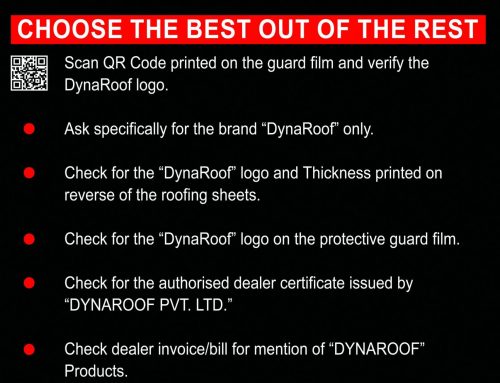

If the applications are not fit for design-load conditions, or properly tested and engineered for their specific application, their failure can cause death, injury, and property or roof damage. For secure roof applications, repairing and replacing system do contact www.Dynaroof.com.

Leave A Comment